Ramin is a PhD student in the group of Professor Mary Ryan. Her research focuses on understanding some of the major degradation processes we see in lithium-ion batteries – which are found in your laptops, calculators, e-bikes, children’s toys. Improving this battery technology, could lead to reduce consumer costs for battery replacement, as well as contribute towards legislative efforts in electrifying the UK.

Ramin is a PhD student in the group of Professor Mary Ryan. Her research focuses on understanding some of the major degradation processes we see in lithium-ion batteries – which are found in your laptops, calculators, e-bikes, children’s toys. Improving this battery technology, could lead to reduce consumer costs for battery replacement, as well as contribute towards legislative efforts in electrifying the UK.

What inspired you to study for a PhD?

I always knew that I wanted to do a PhD because I loved the idea of having a specific research question and dedicating time to answering it (or trying to, at least!). I did my undergraduate degree in Chemical Engineering at UCL, and my master’s project, supervised by Dr Yang Lan, revolved around investigating the colloidal stability of coronavirus-like particles, a highly relevant project during the pandemic. I enjoyed variety of tasks needed to complete my project, such as deriving a theoretical model to simulate the particle behaviour and writing a comprehensive literature review and knew that I wanted to continue working in a research field.

The only question that I had was ‘which field do I want to study in?’, which was quickly answered as I undertook three modules related to energy sources. I immediately learnt about how crucial a role renewable sources play in transitioning our world to net zero. The idea of being able to contribute directly to society and have the opportunity to work with some fantastic researchers is definitely a ‘pinch me’ feeling!

Can you tell us more about your research?

My research focuses on understanding some of the major degradation processes we see in lithium-ion batteries. These batteries can be found in your laptops, calculators, e-bikes, children’s toys, just to name a few applications, but they come with several issues. The biggest challenge they face is their susceptibility to the formation of dendrites.

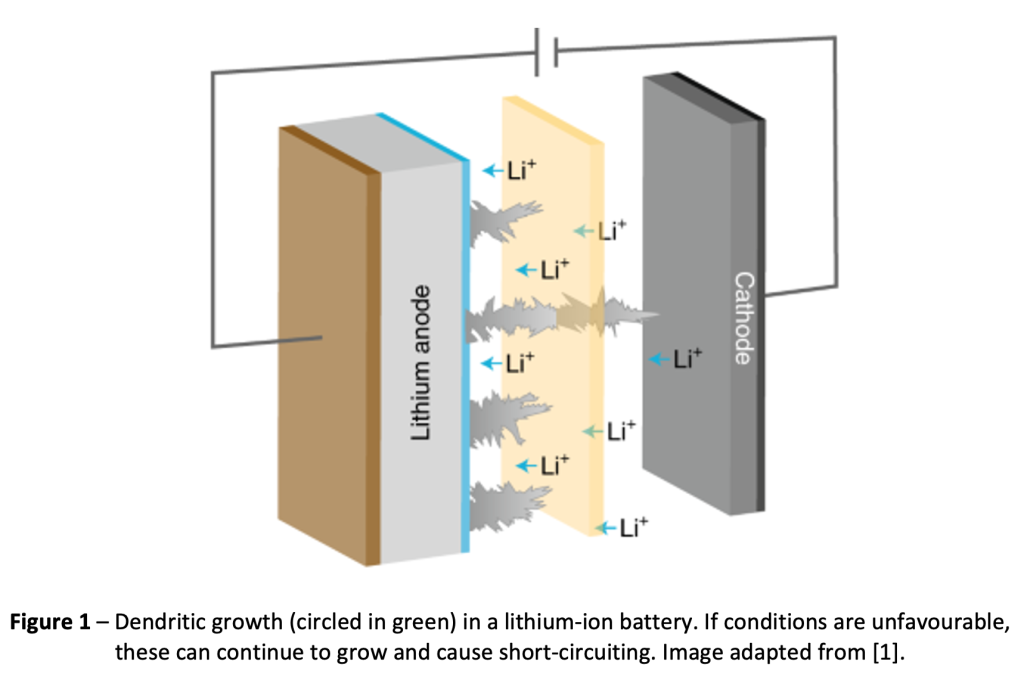

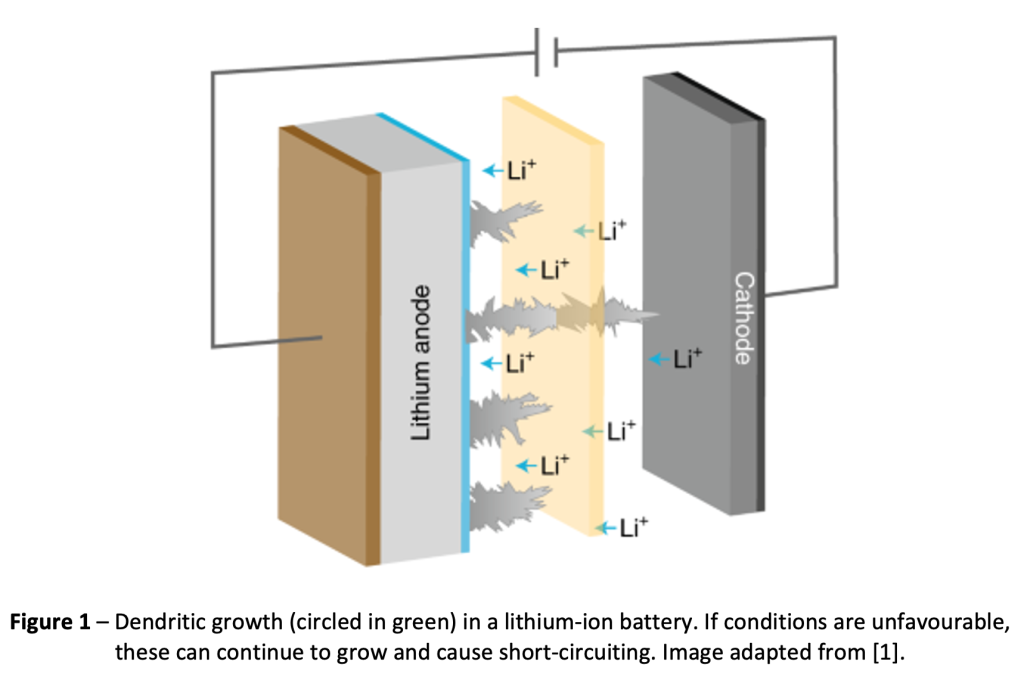

Dendrites are tree-like, lithium-containing extensions that grow on the electrode surface and can potentially create a ’bridge’ between the cathode and anode, causing short-circuiting (and in worst-case scenarios, possible explosions) (Fig. 1). If dendrites are such a major problem in batteries, why can’t we stop them? The answer is a two-fold one.

- While various efforts have been taken to mitigate/ suppress dendrite growth in batteries, such as adding additives into the electrolyte, we cannot truly stop dendritic growth completely until we understand exactly how and why they even grow.

- To do this, we need to be able to visualise how batteries work at the nanoscale, which is a huge challenge due to the limitations in current analytical techniques.

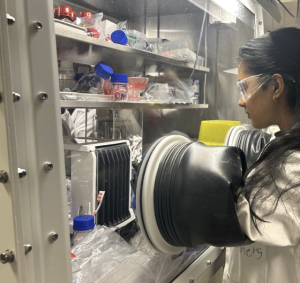

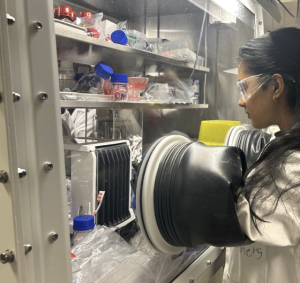

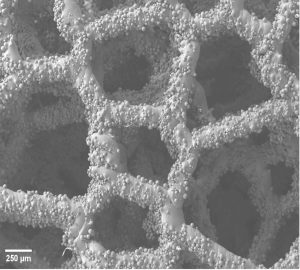

My research aims to utilise the new cryogenic facility (cryo-EPS) in the Department of Materials at Imperial College London, more specifically the atom probe tomography (APT) and transmission electron microscopy (TEM) machines, to investigate the local chemistry and structure of dendrites at the nanoscale, just as they start to grow. An in-situ electrochemical cell is used to simulate early-stage dendritic growth and allow us to visualise this in real time, and this is then characterised to paint a clearer image of the redox/ degradation mechanisms occurring. This information will provide insights into predictive indicators of dendritic growth along the electrode surface and from this, we can devise more effective mitigating measures to suppress their growth. This research is also very cool as it involves plunge-freezing batteries in liquid nitrogen to ‘freeze’ the chemistry in place – this way, we’re able to achieve a snapshot of the battery system in real time!

By improving battery technology, this research aims to reduce consumer costs for battery replacement, as well as contribute towards legislative efforts in electrifying the UK.

What does a typical day involve?

One of the best parts of a PhD is how varied the days are. It’s essentially a four-year project, which means there are lots of tasks to get on with and these tasks differ depending on the stage of your PhD and personal deadlines.

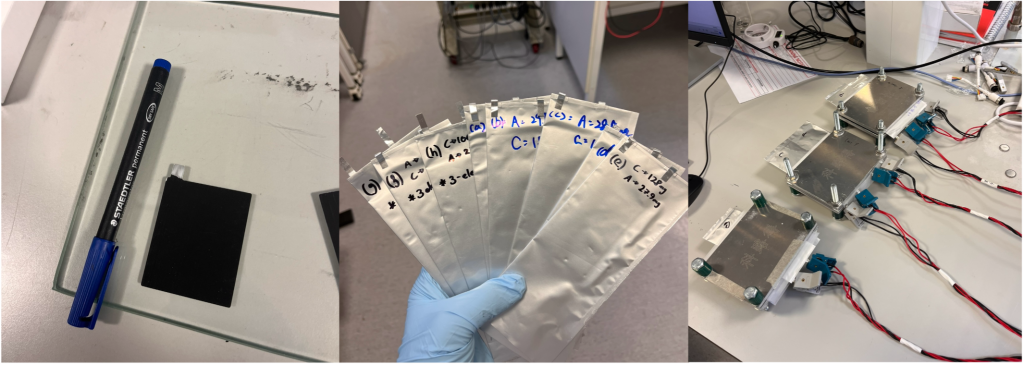

Recently, I’ve been spending my mornings in the lab synthesising electrode materials (which involves a lot of stirring) or coin cell batteries. Testing the battery performance immediately after assembling them is always slightly stressful as you can expect at least one of them to fail! My afternoons are generally spent on desk, which can involve analysing data, putting presentation slides together or reviewing current literature, which has been especially important for a current paper I am working on. My days can also consist of teaching undergraduate students (as a Graduate Teaching Assistant) or supervising master’s students.

Can you tell us more about your research group?

My project ties in electrochemistry with complex materials characterisation techniques and because of this, I have several research groups spanning different research themes. I work primarily under Professor Mary Ryan(Fig. 2a), whose large interdisciplinary group covers nanoscale science and interfaces, including energy materials, bio-sensors and corrosion science.

I also work with Professor Baptiste Gault (Fig. 2b), who spends his time between Imperial and Max-Planck-Institut für Eisenforschung in Düsseldorf and whose research group specialises in APT and correlative TEM for various applications.

My other research groups include the Conroy group, led by Dr Shelly Conroy (Fig. 2c), and the Interfacial Electrochemistry group, led by Professor Ifan Stephens (Fig. 2d). The research of the former focuses on APT and TEM (particularly 4D-STEM strain analysis) and is part of the cryo-EPS facility at Imperial, while Stephens’ group focuses on the large-scale electrochemical conversion of renewable energy to fuels, namely via LIBs, catalysis and fuel cells.

What do you enjoy outside of your PhD?

I like to unwind from my PhD through trying out new recipes, whether it’s through cooking or baking. As science experiments tend to require careful measurements, I like that cooking is generally more flexible and gives me the chance to be slightly more creative. I also enjoy practising creativity through art, especially hyper-realistic drawings and paintings.

I like to unwind from my PhD through trying out new recipes, whether it’s through cooking or baking. As science experiments tend to require careful measurements, I like that cooking is generally more flexible and gives me the chance to be slightly more creative. I also enjoy practising creativity through art, especially hyper-realistic drawings and paintings.

Aside from this, I still enjoy the science realm outside of my PhD, often engaging in outreach events, including school presentations and Student Ambassador days for upcoming engineering students. We also have several group lunches/ dinners per year as part of a research group, including the most recent Christmas lunch with the Conroy group (Fig. 3)!

References:

[1] Babu G, Ajayan PM. Good riddance, dendrites. Nature Energy.

Read PhD Spotlight: Transforming battery technologies in full

Abhi Rajendran is a fourth-year undergraduate student in the Department of Materials. Together with recent alumnus Adam Wu, they have founded a new start-up, AminoAnalytica and are participating in this year’s Venture Catalyst Challenge, Imperial College London’s flagship entrepreneurial competition.

Abhi Rajendran is a fourth-year undergraduate student in the Department of Materials. Together with recent alumnus Adam Wu, they have founded a new start-up, AminoAnalytica and are participating in this year’s Venture Catalyst Challenge, Imperial College London’s flagship entrepreneurial competition.  Ramin is a PhD student in the group of Professor Mary Ryan. Her research focuses on understanding some of the major degradation processes we see in lithium-ion batteries – which are found in your laptops, calculators, e-bikes, children’s toys. Improving this battery technology, could lead to reduce consumer costs for battery replacement, as well as contribute towards legislative efforts in electrifying the UK.

Ramin is a PhD student in the group of Professor Mary Ryan. Her research focuses on understanding some of the major degradation processes we see in lithium-ion batteries – which are found in your laptops, calculators, e-bikes, children’s toys. Improving this battery technology, could lead to reduce consumer costs for battery replacement, as well as contribute towards legislative efforts in electrifying the UK.

I like to unwind from my PhD through trying out new recipes, whether it’s through cooking or baking. As science experiments tend to require careful measurements, I like that cooking is generally more flexible and gives me the chance to be slightly more creative. I also enjoy practising creativity through art, especially hyper-realistic drawings and paintings.

I like to unwind from my PhD through trying out new recipes, whether it’s through cooking or baking. As science experiments tend to require careful measurements, I like that cooking is generally more flexible and gives me the chance to be slightly more creative. I also enjoy practising creativity through art, especially hyper-realistic drawings and paintings.

Dr Jerry Sha is a Research Associate in the group of Professor Stephen Skinner. He joined the Department as an undergraduate student in September 2013.

Dr Jerry Sha is a Research Associate in the group of Professor Stephen Skinner. He joined the Department as an undergraduate student in September 2013. Dr Anna Winiwater is a Research Associate in the group of Professor Ifan Stephens. She joined the Department of Materials this year.

Dr Anna Winiwater is a Research Associate in the group of Professor Ifan Stephens. She joined the Department of Materials this year. Dr Pankaj Sharma is a Research Associate in the group of Professor Fang Xie. He joined the Department of Materials this year.

Dr Pankaj Sharma is a Research Associate in the group of Professor Fang Xie. He joined the Department of Materials this year. Dr Megan Owen is a Research Associate in the group of Professor Sir Robin Grimes. She joined the Department of Materials in 2022.

Dr Megan Owen is a Research Associate in the group of Professor Sir Robin Grimes. She joined the Department of Materials in 2022. Dr Apostolos Panagiotopoulos is a Research Assistant in the group of Professor John Kilner. He joined the Department of Materials in 2018 as a Research Postgraduate.

Dr Apostolos Panagiotopoulos is a Research Assistant in the group of Professor John Kilner. He joined the Department of Materials in 2018 as a Research Postgraduate.

My research group (

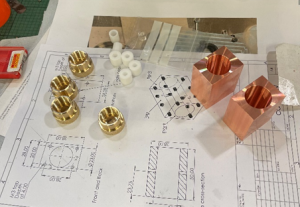

My research group ( Mike: Workshops are important to produce of a wide range of goods. When you think about it, everything around you is likely created in a type of workshop, from transport to household items and clothing – it just depends on the size, scale, and capability of the facility. In the Department of Materials, we focus on making components that can support research or teaching – and we are always up for a new challenge!

Mike: Workshops are important to produce of a wide range of goods. When you think about it, everything around you is likely created in a type of workshop, from transport to household items and clothing – it just depends on the size, scale, and capability of the facility. In the Department of Materials, we focus on making components that can support research or teaching – and we are always up for a new challenge! Most parts machined in the workshop are made from metal or plastic. In recent years, we have witnessed a growing demand for the use of new materials such as Peek. Peek is a fairly new material. It has become an increasingly popular material, replacing PTFE for sample holders, as it doesn’t contaminate the material which is being tested, is a more stable material from a machining perspective and is able to operate at higher temperatures.

Most parts machined in the workshop are made from metal or plastic. In recent years, we have witnessed a growing demand for the use of new materials such as Peek. Peek is a fairly new material. It has become an increasingly popular material, replacing PTFE for sample holders, as it doesn’t contaminate the material which is being tested, is a more stable material from a machining perspective and is able to operate at higher temperatures. What do the team most enjoy about their roles in the workshop?

What do the team most enjoy about their roles in the workshop?

The newly discovered method at AlixLabs allows ALE to be selectively performed on inclined surfaces – which in turn can be fabricated by epitaxial growth and dry etching. Our task was to get an approximate of how GaP (Gallium Phosphide) will be etched if chlorine (Cl) was used as the plasma and obtain the values of surface energy required for it. To achieve this, we used the Espresso and Jaguar software provided through Schrödinger, which allowed us to build a GaP crystal and turn it into a slab having some amount of vacuum space. Upon adding a Cl

The newly discovered method at AlixLabs allows ALE to be selectively performed on inclined surfaces – which in turn can be fabricated by epitaxial growth and dry etching. Our task was to get an approximate of how GaP (Gallium Phosphide) will be etched if chlorine (Cl) was used as the plasma and obtain the values of surface energy required for it. To achieve this, we used the Espresso and Jaguar software provided through Schrödinger, which allowed us to build a GaP crystal and turn it into a slab having some amount of vacuum space. Upon adding a Cl All in all, we really enjoyed the experience of being able to contribute our part and have this opportunity to travel to Sweden and learn more about AlixLabs and semiconductors. This has certainly deepened our knowledge in this research area, and we are very grateful to continue our alliance with them.

All in all, we really enjoyed the experience of being able to contribute our part and have this opportunity to travel to Sweden and learn more about AlixLabs and semiconductors. This has certainly deepened our knowledge in this research area, and we are very grateful to continue our alliance with them.